Manufacturing Planning and Analysis Reports

Create custom Fishbowl Manufacturing Planning Reports such as WO travelers, BOM Reports, Advanced Manufacturing performance, and Analysis reports to plan inventory, materials, capacity, and production.

Manufacturers can use a production scheduling system to automate many processes and run more efficiently. Fishbowl Manufacturing Planning Reports will ensure production forecasting, resource planning, production scheduling, and order fulfillment.

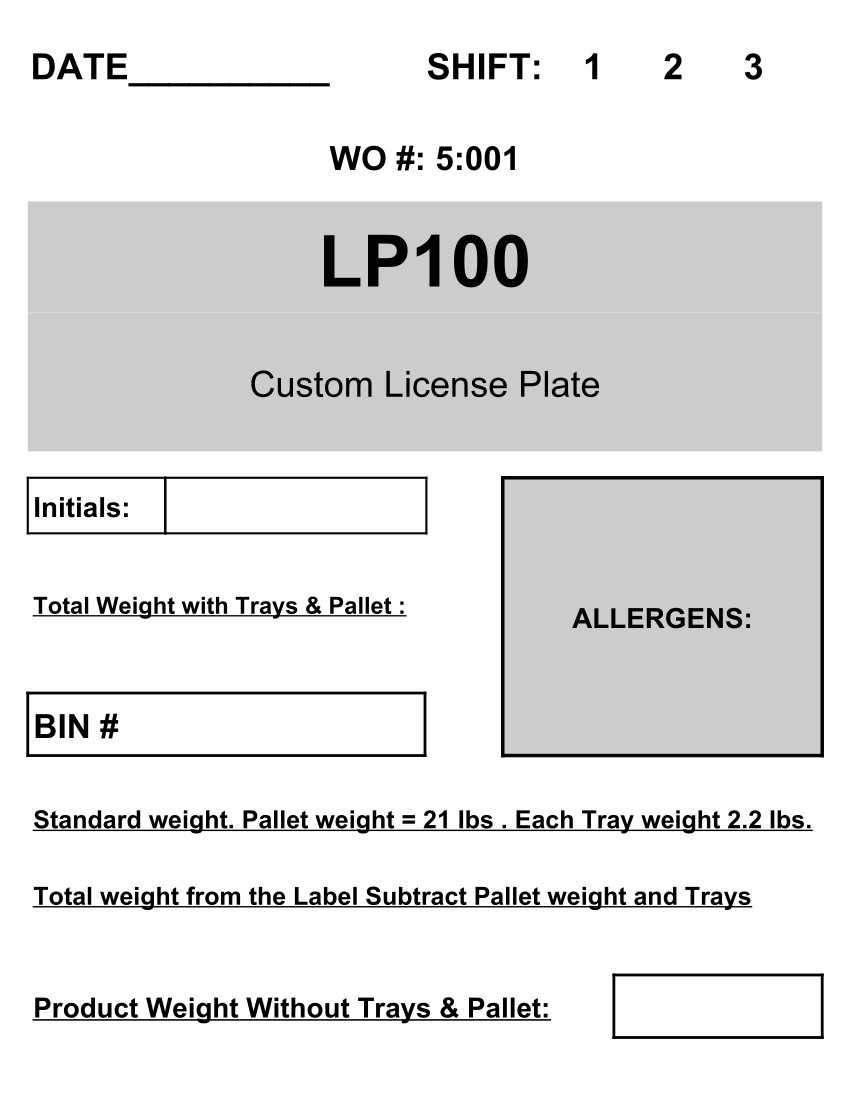

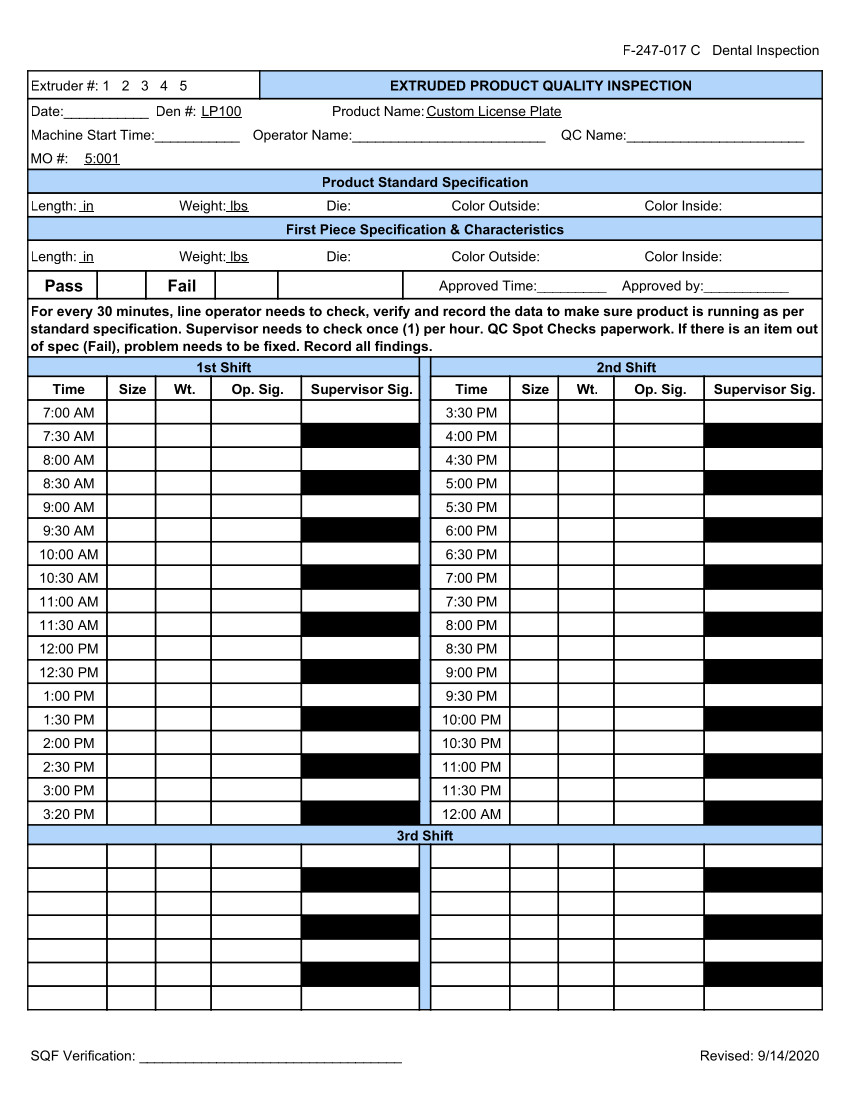

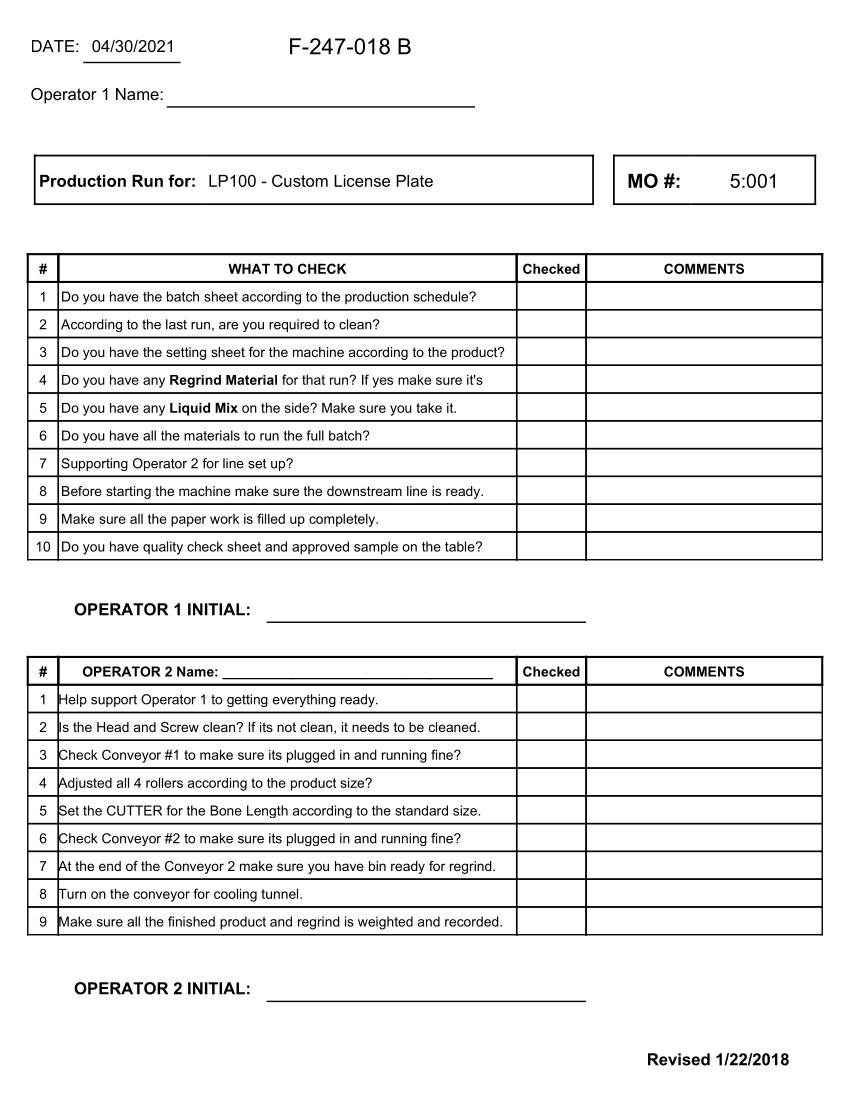

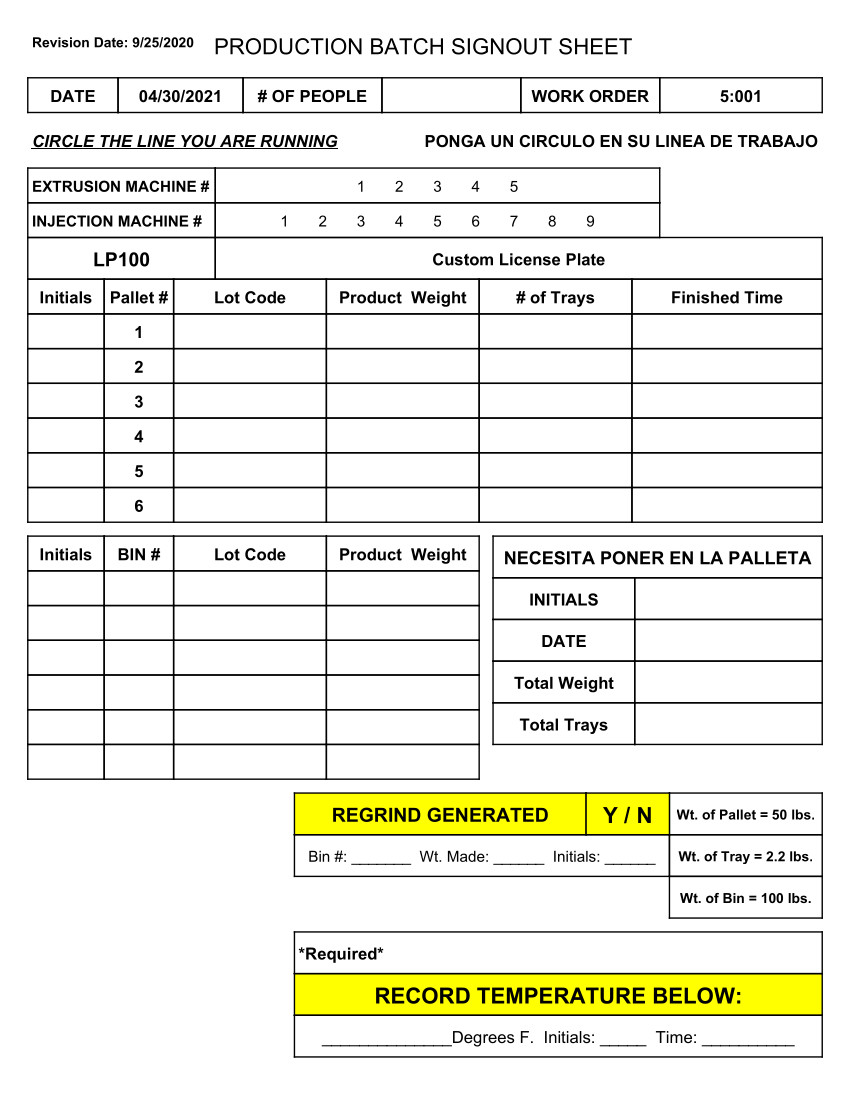

Work Order Docs

*this report prints 4 documents at once

This is a series of reports (Pallet Sheet, Product Quality Inspection, Operator Checklist Report, Sign Out Sheet Report) that can all be used to assist in the manufacturing process. These Fishbowl reports are printed and handed to the manufacturing team, allowing them to properly perform quality control as well as keep track of all of the steps involved in production.

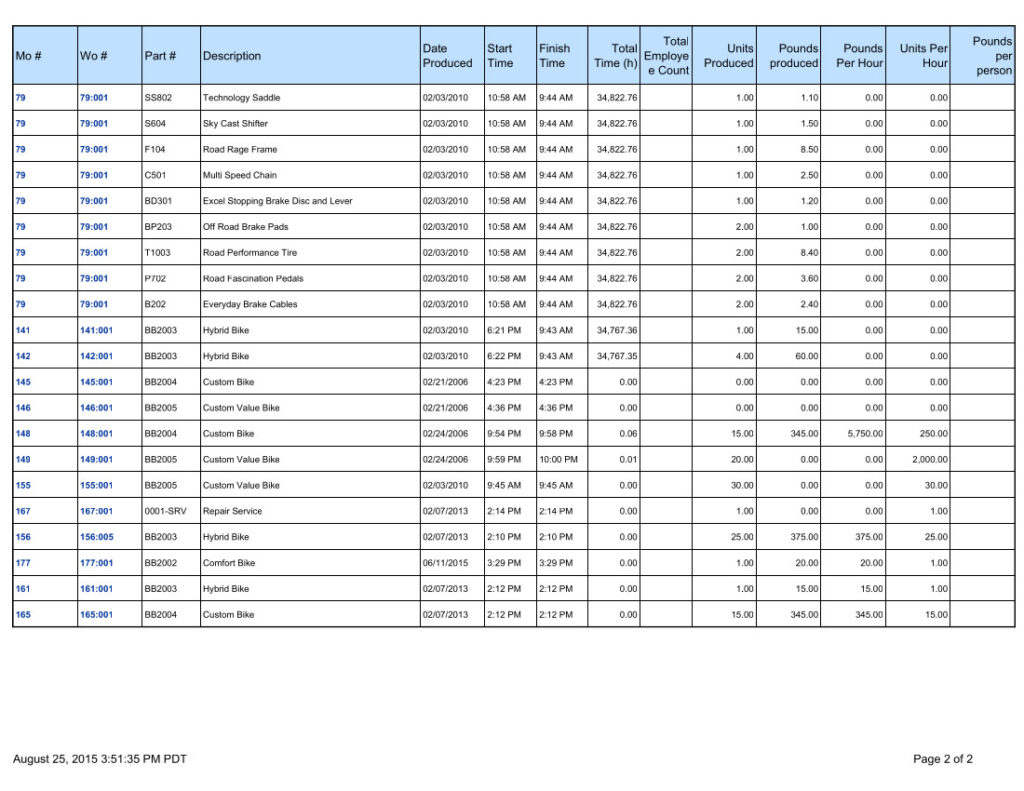

Manufacturing Performance Report

This Fishbowl report reviews the performance of each Work Order, displaying information such as Date Produced, Start Time, Finished Time, Total Time, Units Produced, Pounds Produced, Pounds Per Hour, Units Per Hour, and Pounds per person.

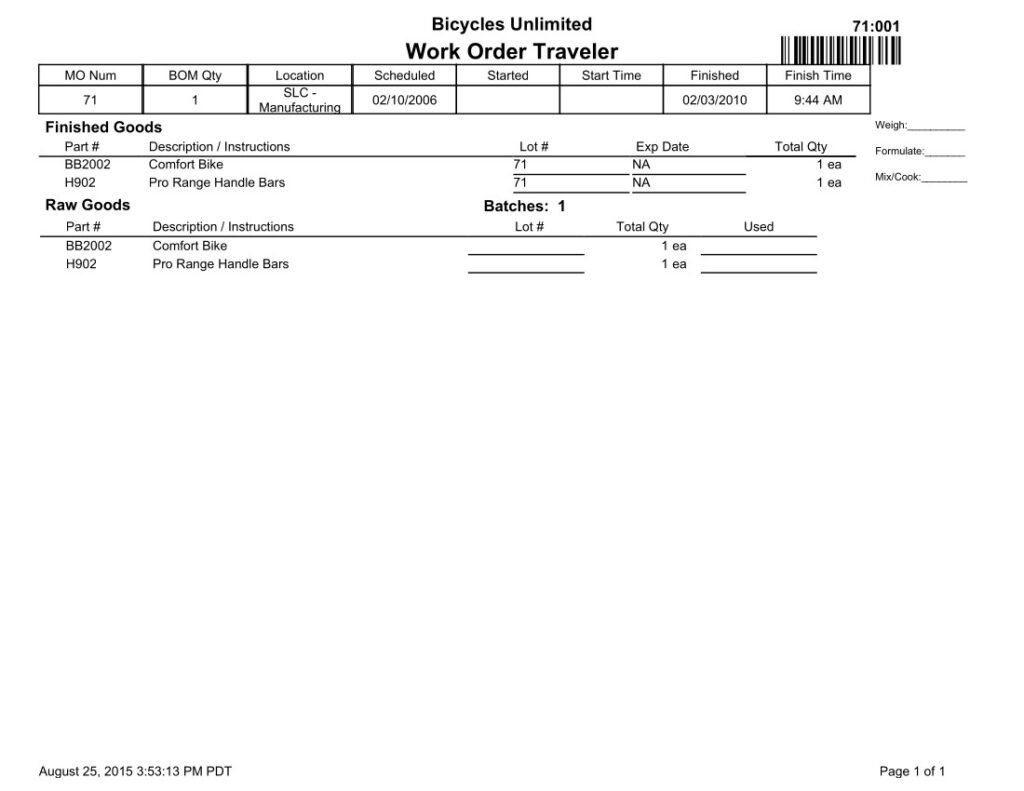

WO Traveler Report

This is a customized Fishbowl Work Order Traveler that adds Batch logic to the report. Fishbowl Manufacturing Reports

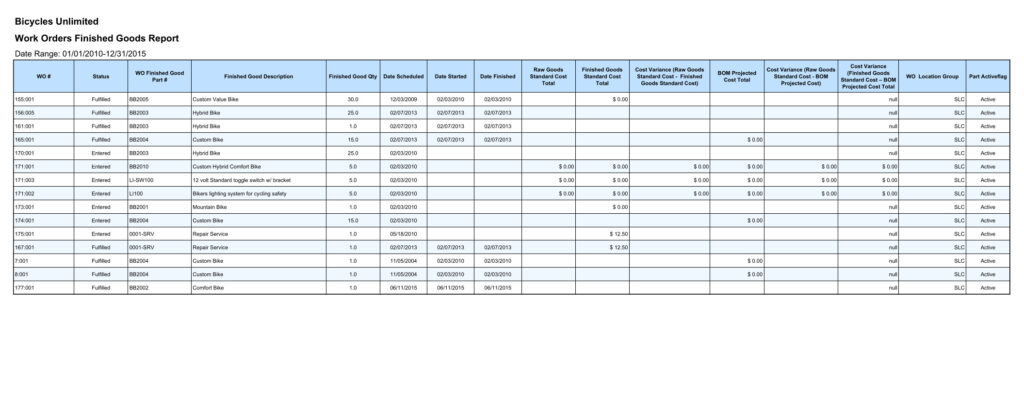

WO Finished Good Report

This report reviews all the work orders fulfilled within the date range and displays information such as Raw Goods Standard Total Cost, Finished Goods Standard Total Cost, Cost Variance, BOM Projected Total Cost as well as other information pertinent to the Work Order Finished Goods.

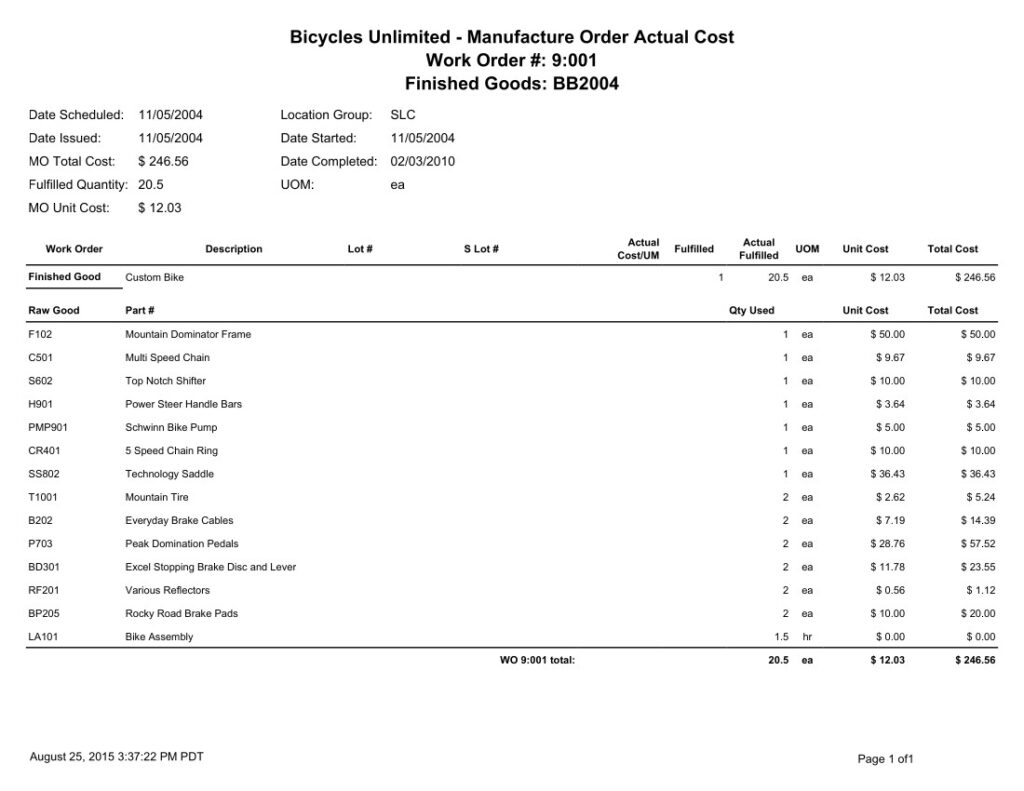

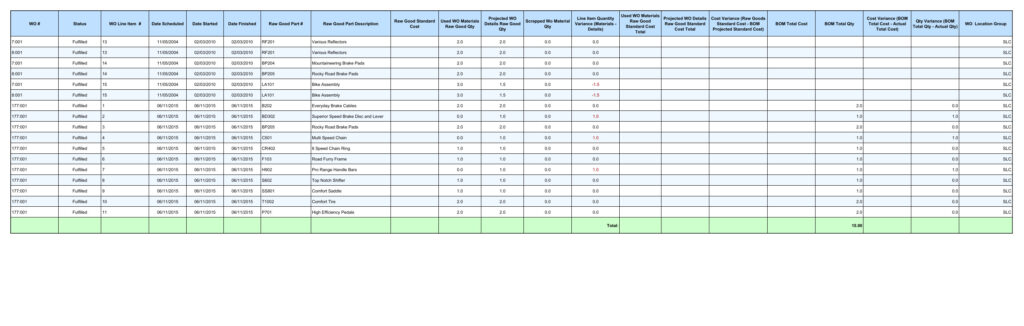

WO Raw Goods Report

This Fishbowl Manufacturing report reviews all the Work Orders fulfilled within the date range together with the Raw Goods consumed, and displays the Raw Goods information, such as Qty Used, Projected WO Usage, Qty Scrapped, Line Item Qty Variance, BOM Total Cost, and other information pertinent to Raw Goods on the Work Orders.

Interested in our services?

Connect with us to discuss your needs.